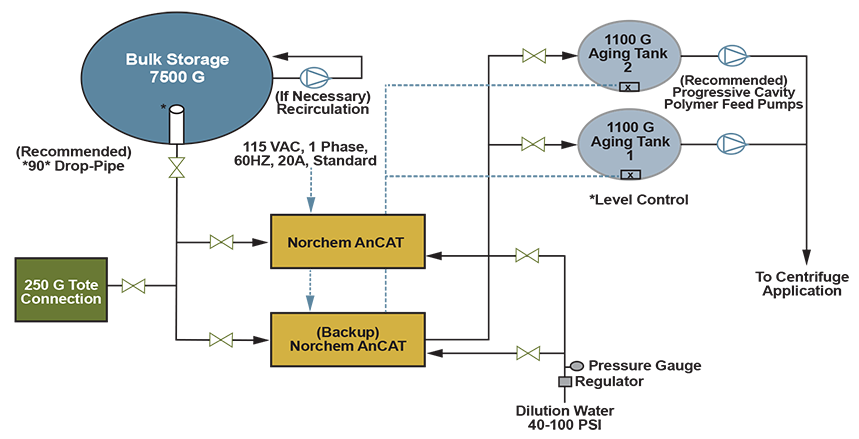

Midwest Chemical & Equipment (MWCE) contributed to system design and chemical understanding in the transition from Mannich polymer to emulsion polyacrylamide flocculant on the sludge dewatering application at a suburb sewer district of Chicago. MWCE incorporated Norchem polymer preparation systems and diluted polymer aging tanks to achieve high efficiency of the flocculant in dewatering centrifuges.

The water reclamation district (WRD) was using a cationic polymer flocculant manufactured by the Mannich-Reaction.

- Strong odors present

- Usage of over 1,000 gallons per day (GPD) on neat Mannich polymer

- Addition of CO2 gas to adjust pH for better flocculation

- Inconsistent total cake solids ranging from 22-24% on produced biosolids

- Centrate problems with foaming and high TSS

A system for injecting activated emulsion-based polymer was designed, proposed and implemented at the WRD, with the following goals achieved:

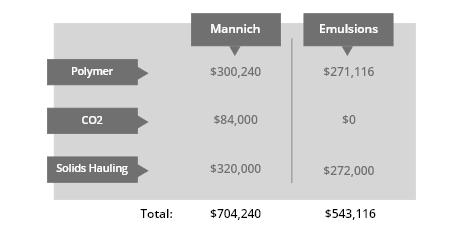

- Significant reduction of polymer usage and cost

- Eliminated CO2 addition

- Stabilized dewatering performance (cake/concentrate)

- Usage reduced to less than 70 GPD

- Cake solids increased to 24-25%

- Less foaming/total solids released in the centrate