Strategically Applying Magnesium Hydroxide for Odor and Corrosion Control in Collections Systems

By: Andrew Rossetti

Abstract Summary

A new odor control chemical and feed program was studied at two regional municipal wastewater plants in their collections systems. At Fox Metro Water Reclamation District, a 60% Magnesium Hydroxide slurry, ALKAMag+, supplied with technical support through Midwest Chemical & Equipment (MCE), was applied and performance studied. Portable gas meter/loggers were deployed in manholes downstream from the lift station feed point to gather background data, establish a unique strategic dosing window, and measure hydrogen sulfide gas (H2S) reduction. Daily peaks in H2S were reduced from >40ppm to 2ppm with ALKAMag+. MCE repeated this method with similar results at Wausau Wastewater Treatment Plant, reducing H2S daily average from >90ppm to 19ppm.

Introduction/Background

Fox Metro Water Reclamation District received persistent odor complaints in specific areas of their collections system. The plant tasked Baxter & Woodman (BW) to study alternative odor control methods including chemical addition to determine an effective, economical solution.

Calcium nitrate had been previously tried. However, odor complaints continued, particularly in summer months, even at higher feed rates. Magnesium hydroxide was selected as a possible solution, because it can continuously control the pH above neutral, where hydrogen sulfide is primarily dissolved in its liquid phase, HS–. Magnesium hydroxide was also considered for the cleaning benefits of the hydroxide molecules, which would potentially scour the slime layer on the inner pipe wall containing sulfate reducing bacteria.

Prior to the pilot, the previous Nitrate-based odor control chemical and ozone systems were turned off for one week at the problem lift station, Reckinger Road. Using an Acrulog mobile H2S gas logger, the background H2S data was logged. The peak H2S level at the first downline manhole was 15ppm, and peak windows were daily between 7PM and 8AM. Also, a baseline sample of slime was taken from the pipe wall for comparison after ALKAMag+.

At Wausau Wastewater Treatment Plant there was no background odor control chemical being fed at the lift station, and the flow had a much higher concentration of industrial waste. The H2S background levels were more significant and contributing to significantly worse odors in the system than at Fox Metro. The plant staff reported odor problems had arose shortly after a pipe lining project. It was suspected that without corrosion occurring on the now-lined concrete pipe, more H2S was carried through the lines in gas form. The background H2S daily average measured at the downstream manhole was >90ppm, and the most severe peak windows were during overnight hours, similar to Fox Metro Water Reclamation District.

Main Content

The methods and results from these two odor control pilot studies are described below.

Fox Metro Water Reclamation District:

Method:

To begin the pilot, a continuous flow of 75 GPD of ALKAMag+ was applied to the lift station influent. The estimated lift station flow was 1MGD. A Watson Marlow, Qdos 60 was used to feed the slurry out of a 1,000-gallon mini bulk tank with mixer.

The average and peak H2S was not significantly changed at this continuous dosing rate, and the windows of H2S release were still observed daily between the overnight hours while the system flow was relatively stagnant.

It was suspected that a higher dosage of ALKAMag+ was initially required to scour the built-up slime/biosolids layer from the pipe after years of Nitrate addition. However, it was decided that a timed release of ALKAMag+ into the lift station during the hours of low flow activity may be more effective at the same chemical dosage. At this stage, all chemical was shut off for one week to get back to a baseline before the overnight dosing was tried.

To start the overnight feed, the Watson Marlow pump was put on a timer to feed at a higher rate during 7pm-7am. The pump also turned on for five six-minute intervals throughout the day to prevent the slurry from clogging in the feed lines. The overall usage target was still 75GPD.

Results:

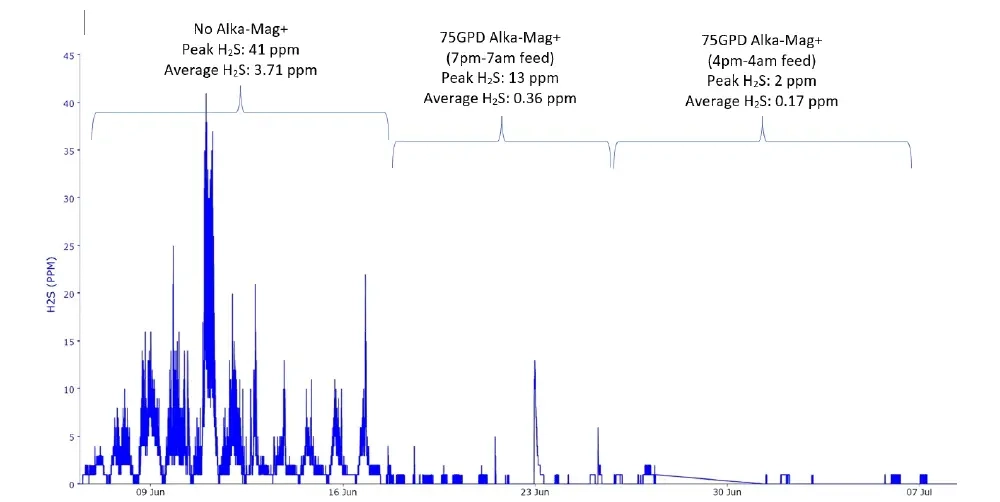

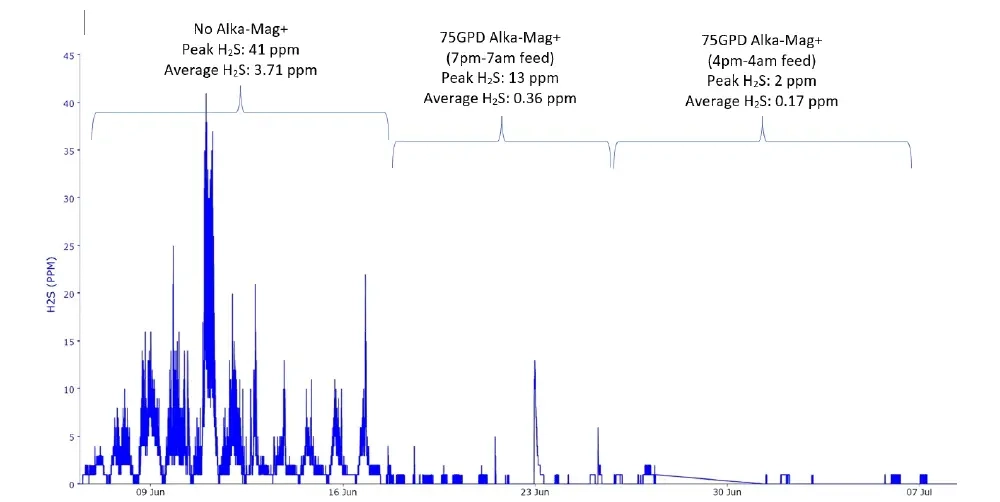

Figure1: H2S levels during Fox Metro Water Reclamation District pilot

The initial feed window of 7pm to 7am did reduce the H2S from 41ppm to 13 ppm. However, there was still H2S formation starting each evening. So, the feed window was moved up to 4pm to 4am. Then, the daily peak H2S was in the manhole was reduced to 2ppm.

A sample of sewer line slime was also taken after the mag had been running for several weeks. The comparison showed less sulphate reducing bacteria accumulation with ALKAMag+.

Wausau Wastewater Treatment Plant:

Method:

The overnight, 4pm to 4am feed schedule was also applied at Wausau. The lift station flow was also estimated at 1MGD. The same feed rate, 75 GPD overall, was applied ahead of the lift station.

It was a challenge keeping the Qdos flowing on this application due to pump-head wear and clogs forming at times when the chemical was off. This contributed to some days where the ALKAMag+ was dosed under target, and more H2S was consequently observed. For future applications hose pumps, like the Brendal APEX, have proven more resilient against clogs and abrasion with magnesium hydroxide slurry.

Results:

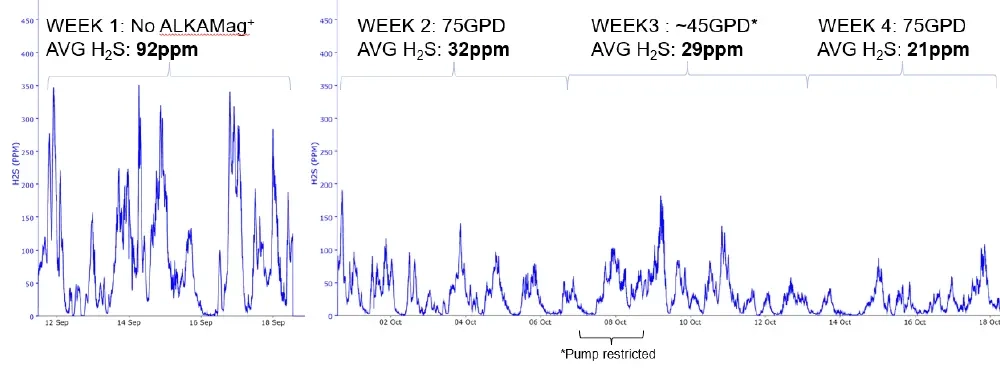

The average H2S level measured in the downline manhole was reduced from 92 ppm to 21 ppm by week 4.

Conclusions:

Both plants are evaluating feed systems on future lift station construction projects. FMWRD comments: “While the product works and the science behind it is sound, Fox Metro is still determining if it is the right solution for our pump station, as significant investment in the infrastructure will need to be done to implement it reliably it at Fox Metro’s facility.” Feeding magnesium hydroxide slurry for odor control on a schedule that is inversely proportional to the system flow will make chemical usage targeted and economical. Both plants reported a reduction in biofilm, as the ALKAMag+ scoured the pipe walls.

Broader Impacts

Many Midwest municipal wastewater utilities experience odor and corrosion problems related to H2S formation in their sewer. Contributing factors can vary depending on the type of wastewater, flow, and detention time. Alternative chemical injection methods (calcium nitrate, ozone, hydrogen peroxide) have limitations; specifically, the problems include continued downstream effectiveness, increased pipe biofilm, and increased Nitrate loading to the plant. Positive results were observed using ALKAMag+, and other information was learned which will be useful for feeding odor control chemicals on future applications.

Magnesium hydroxide slurry is a safe, non-hazardous, and economical chemical. It provides other downstream benefits in the treatment process, because it carries high levels of alkalinity which only dissolve in the presence of acids. If magnesium hydroxide continues to show odor and corrosion control effectiveness, it can be an attractive option for municipal collections systems.

The outline of the accompanying presentation will be as follows:

- Odors in Sewers

- How H2S forms in Sewer Pipes

- High infrastructure costs and community issues

- Contributing Factors

- Flow

- Type of Wastewater

- Temp

- pH

- Chemical control Methods

- Chemical oxidants, reaction mechanism, benefits, drawbacks

- Nitrate addition, reaction mechanism, benefits, drawbacks

- Continuous pH adjustment

- H2S Solubility

- Holding pH to keep H2S in solution

- Scouring slime layer

- Magnesium Hydroxide properties

- Challenges

- Fox Metro Pilot

- Background

- Pilot System Design

- Initial continuous feed method

- Overnight feed method

- Results

- Wausau Pilot

- Background

- Method

- Results

- Magnesium Hydroxide Slurry

- Supply, storage, feed systems

- Added process benefits

- Challenges/Lessons Learned

- Feeding slurry, avoiding pump restrictions

- Determining chemical dosage

- Optimizing feed schedule

Contributors: Peter Svebakken, Baxter & Woodman (co-presenter); Ben Brooks, Wausau Wastewater Treatment Plant; Matt Giese and Evan Semrau, Midwest Chemical & Equipment